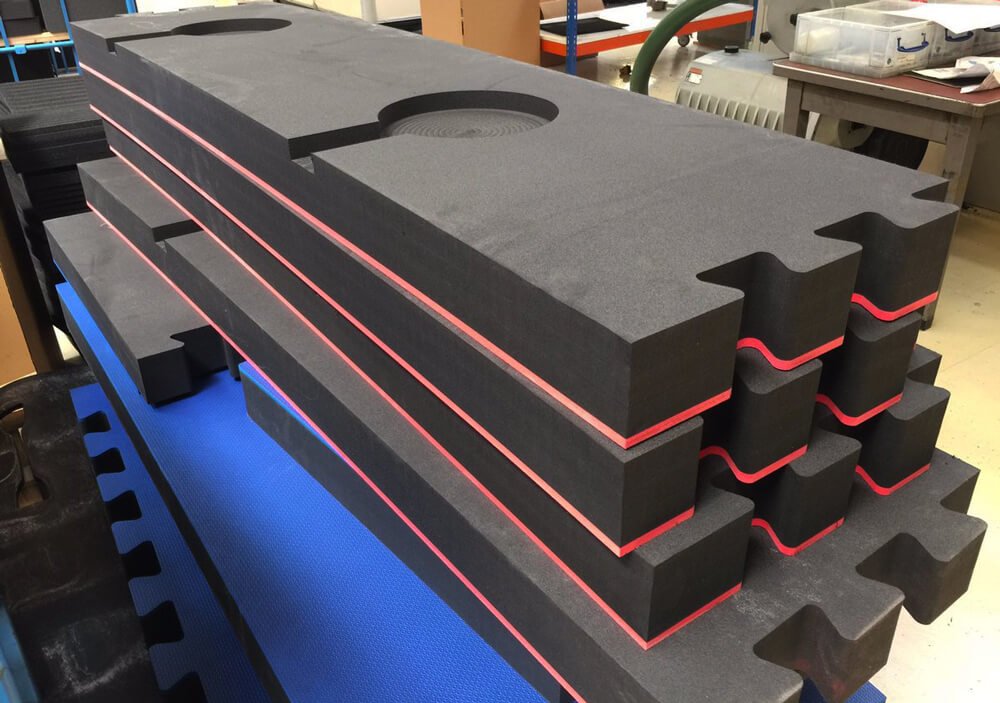

Custom foam, tailored specifically in size and shape, is an essential resource for numerous industries. Its advantages for businesses are significant. By utilizing custom foam pieces, companies can ensure that their products are securely packaged and have a more polished appearance. This adaptability enables the creation of:

- Foam shapes that align perfectly with required specifications

- Non-traditional designs beyond standard rectangular or square forms

- Accurate fittings for particular items or designated spaces

We explore how different sectors incorporate this material into their everyday functions.

Top 3 Industries Utilizing Custom Cut Foam

- Packaging and Shipping: In this sector, foam inserts are extensively employed to safeguard fragile, delicate, or costly items. This includes electronics, precision instruments, and glassware. By using custom foam inserts, businesses can secure products during transit, significantly minimizing the risk of damage and avoiding expensive replacements. Without custom foam, the likelihood of product damage in shipping increases substantially, prompting companies worldwide to adopt foam packaging to save costs and maintain customer satisfaction.

- Automotive and Aerospace: The automotive and aerospace industries also benefit from custom foam. It plays a crucial role in noise reduction, vibration damping, insulation, and cushioning for sensitive components. These foam parts protect delicate systems while enhancing passenger comfort and safety. For instance, the interiors of vehicles and aircraft often include foam elements that contribute to a more pleasant travel experience, promoting a quieter and more comfortable ride. The versatility and precision of custom foam are essential in these applications.

- Construction and Insulation: The construction sector frequently utilizes custom foam, particularly for insulation and soundproofing purposes. Foam materials are custom-cut to fit specific structures precisely, aiding in energy efficiency and noise reduction. Custom foam components are especially valuable in projects that require high precision, such as specialized architectural designs or acoustic treatment efforts. Its ability to be precisely cut ensures it meets even the most stringent construction demands effortlessly.

Custom Foam Solutions from Livedale

Livedale specializes in manufacturing custom foam pieces tailored to your specifications, regardless of size or shape. Custom foam cut to size is a valuable service that offers extensive benefits to various industries, Utilizing advanced CNC technology, they create highly precise foam components that cater to the needs of various industries. Their products are of superior quality and competitively priced, making them a trusted choice for businesses seeking reliable foam solutions.

Streamlined Ordering Process for Custom Foam

Ordering custom foam from Livedale is straightforward and can be easily completed online. Their simple five-step process includes:

- Choose from a wide range of standard shapes or request a custom design tailored to your project.

- Carefully measure your items in inches, millimeters, or centimeters to ensure a proper fit.

- Select the appropriate foam grade for your specific needs, whether for cushioning, insulation, or other uses.

- Optionally, enhance the foam’s performance with add-ons like stockinette or Dacron.

- Finalize your order online or reach out to their team for assistance, with reliable delivery options available.

Conclusion

Custom foam plays a vital role across many industries, from packaging delicate items to providing insulation for construction projects. Its versatility and precise customization capability make it an invaluable asset. Businesses looking to protect their products, enhance performance, or design unique solutions can rely on custom foam offerings from Livedale.

For more details, visit https://livedale.co.uk/